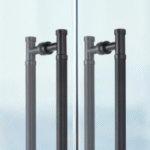

Primary vs recycled Al—better corrosion resistance?

Corrosion concerns drive material choices. When comparing primary and recycled aluminum, understanding their resistance reveals key differences impacting durability.

Primary aluminum offers better corrosion resistance than recycled aluminum due to its higher purity and controlled manufacturing processes, which reduce impurities that cause corrosion.

My experience in the hardware trade highlights that primary aluminum, smelted from bauxite, keeps impurities like sodium and potassium minimal. These elements can prompt corrosion, so controlling them ensures a consistent protective oxide layer in adverse environments. In contrast, recycled aluminum often retains residual impurities, creating potential corrosion points over time.

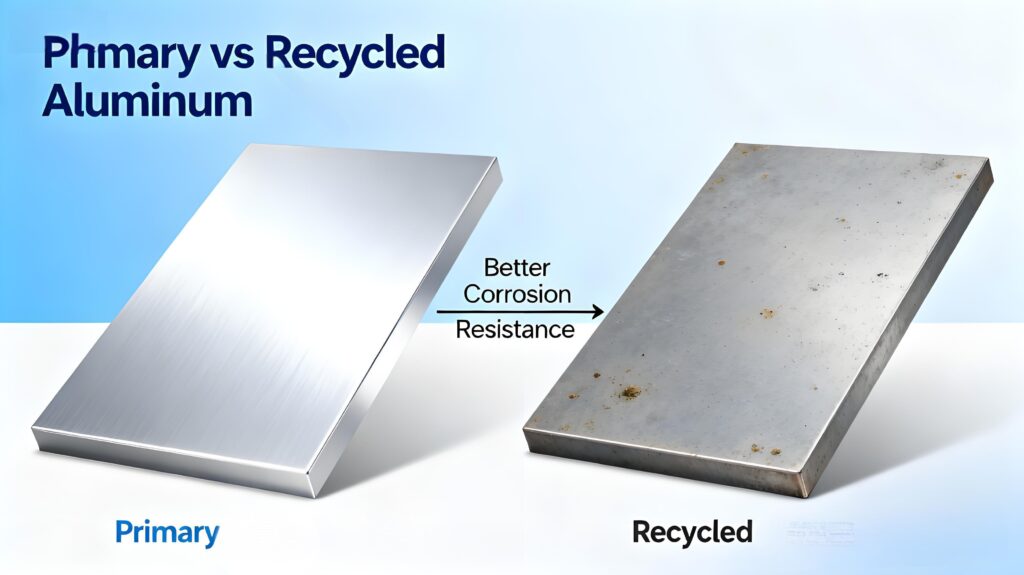

Does aluminum rust more easily in salt water?

Saltwater exposure pushes corrosion boundaries, challenging metal longevity without diligent protection.

Aluminum does not rust like iron but corrodes more easily in saltwater due to chloride ions that penetrate protective oxide layers.

Saltwater environments accelerate aluminum corrosion. Chloride ions disrupt the aluminum oxide layer, increasing susceptibility to pitting. This effect is particularly noted in coastal projects. For clients, we advise aluminum with enhanced coatings or anodized layers to maintain integrity in these settings.

| Environment | Corrosion Risk | Protective Measures |

|---|---|---|

| Saltwater | High | Anodizing, Coatings |

| Freshwater | Moderate | Standard Protection |

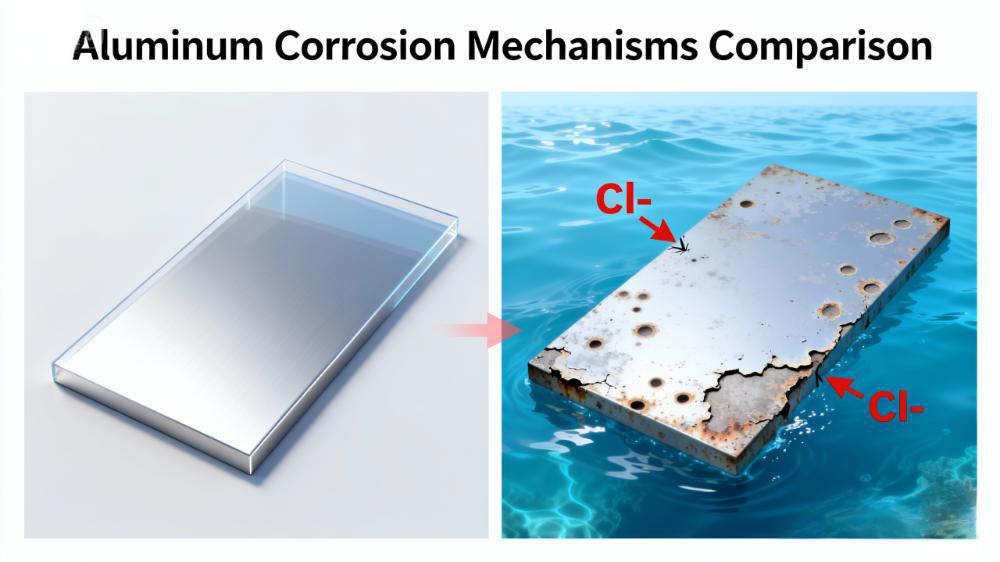

How many more years can aluminum last with anti-rust coating?

Applied coatings extend lifespan, balancing aesthetic appeal with protection in aggressive conditions.

An anti-rust coating can significantly prolong aluminum's lifespan, potentially doubling its resistance time against corrosive elements.

From supplier feedback, coating treatments like anodizing or powder coating offer robust protection. These barriers enhance resistance against oxidation, particularly in high-humidity or industrial areas. Properly applied, aluminum can withstand decades of exposure, maintaining both its look and function, making it a reliable choice for outdoor furniture or building projects.

| Treatment | Estimated Lifespan Extension |

|---|---|

| Anodizing | Up to 100% longer |

| Powder Coating | 50-70% longer |

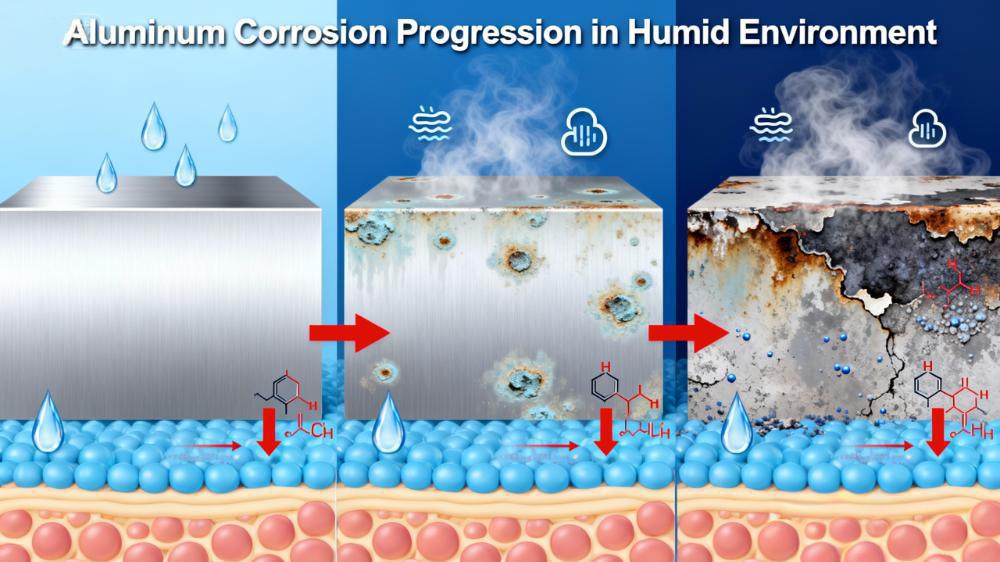

How soon does aluminum corrode in humid environments?

Humidity poses a persistent threat, urging proactive design and protective practices across industries.

In humid conditions, aluminum begins to show corrosion signs within a year if not protected, due to accelerated oxidation from moisture.

In humid climates, moisture perpetuates aluminum's oxidation. Without preventative coating or regular maintenance, this can manifest within months. By discussing these realities with clients, we often recommend additional treatments or periodic checks to mitigate early signs of deterioration and preserve product integrity.

| Environmental Factor | Corrosion Speed | Prevention Strategy |

|---|---|---|

| High Humidity | Quick (within months) | Regular Maintenance |

| Moderate Humidity | Slower | Standard Care |

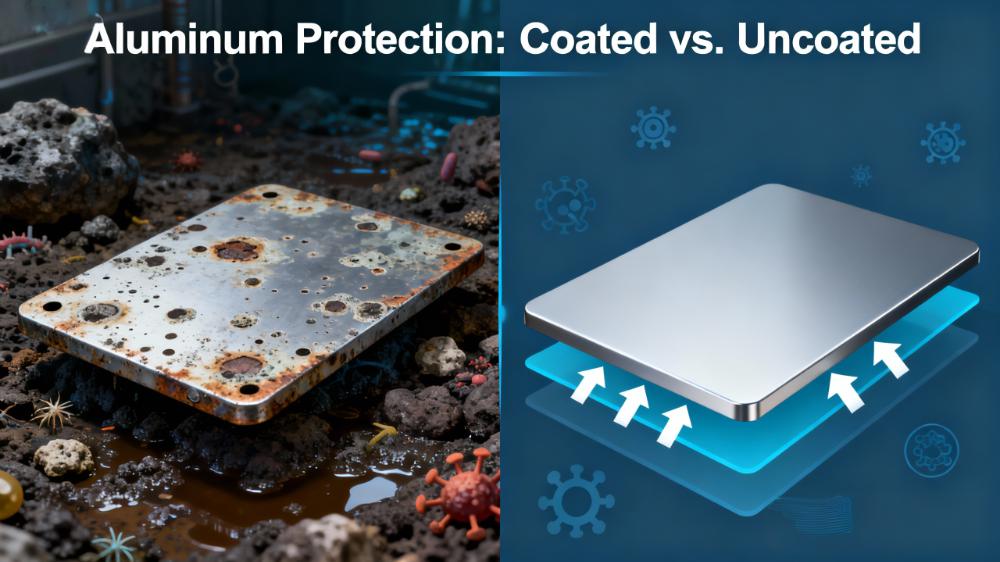

How to better prevent corrosion of aluminum outdoor parts?

Outdoor applications demand foresight; corrosion prevention combines material science and maintenance for lasting solutions.

To prevent corrosion in aluminum outdoor parts, use coatings like anodizing, choose high-purity materials, and ensure regular cleaning to maintain protective layers.

Our strategy involves selecting high-purity primary aluminum for outdoor hardware, supplemented by protective coatings. These layers, reinforced by regular cleaning, keep oxide films intact, especially around coastal or humid environments. Educating clients on proper care techniques often helps sustain the material beyond its typical lifespan.

| Prevention Method | Effectiveness | Application Context |

|---|---|---|

| Anodizing | High | Coastal/Outdoor |

| Regular Cleaning | Moderate | Urban/Industrial |

Conclusion

Primary aluminum's purity offers superior corrosion resistance, especially in challenging environments. Combining treatments ensures long-lasting durability for outdoor applications.